© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

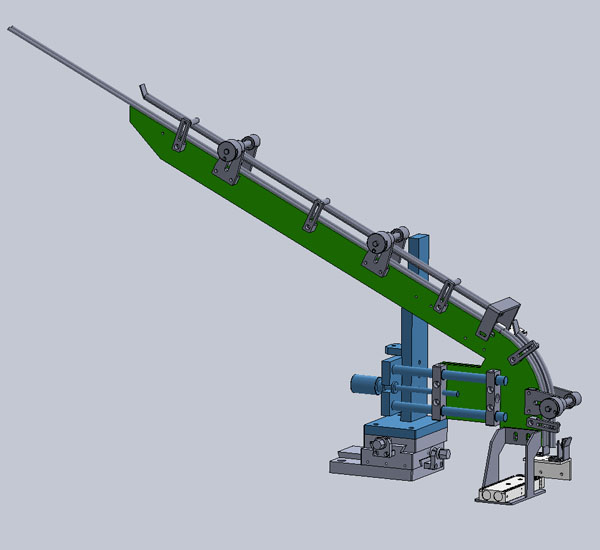

Engine valve seat grinding machine is suitable for grinding seat face of inlet valve and exhaust valve. Wide application range, convenient adjustment, reliable performance, stable precision, using advanced PLC programmable controller, Driven by servo motor.

|

Stem diameter :

|

|

|

Overall length :

|

|

|

Head diameter:

|

|

Engine valve seat grinding machine is suitable for grinding seat face of inlet valve and exhaust valve. Wide application range, convenient adjustment, reliable performance, stable precision, using advanced PLC programmable controller, Driven by servo motor. It has excellent characteristics such as high precision, high stability and high cost performance.

Engine valve seat grinding machine structured as a motor-driven grinding wheel for high-speed rotation. The principle is to grind the size, precision, and smoothness of the parts. Ranging from stem diameter: 5-8 mm, head diameter: 20-50 mm, overall length: 80-150 mm. The machine can single production and also can be connection production. Our equipment is continually upgraded with latest technologies in processing engine valve.

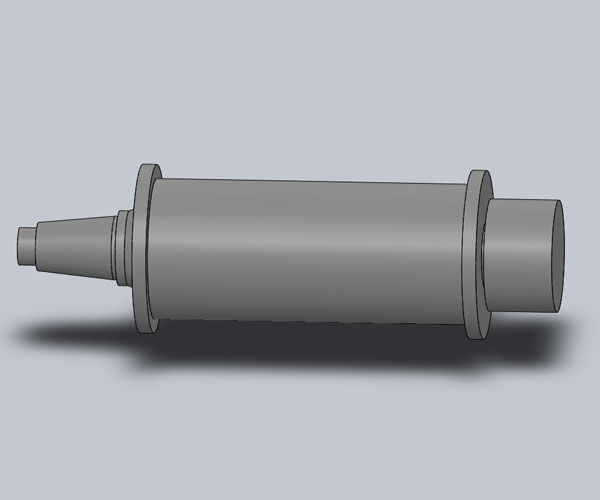

Mechanical Spindle 6000 rpm high-speed spindle. Adapts Germany FAG precision bearing. High accuracy and easy to maintenance and changeover One year warranty |

Control system Adapts Mitsubishi PLC Control system, Mitsubishi motion system & Mitsubishi touch screen All parameters can be set and display on touch screen Can store more sets program, you can choose according to different process technology |

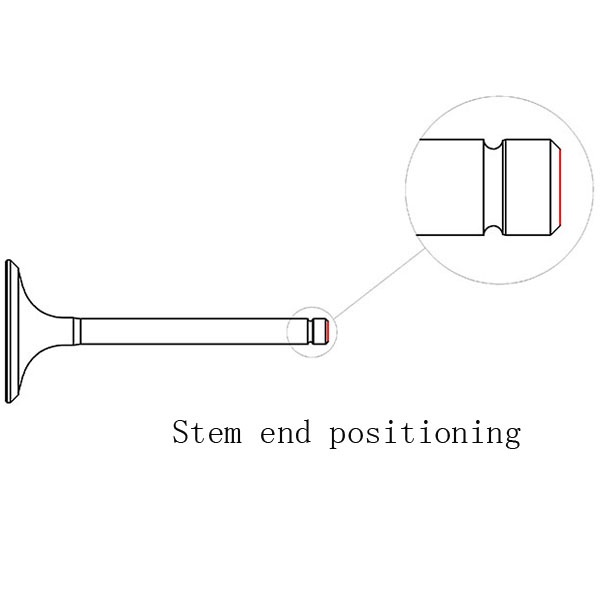

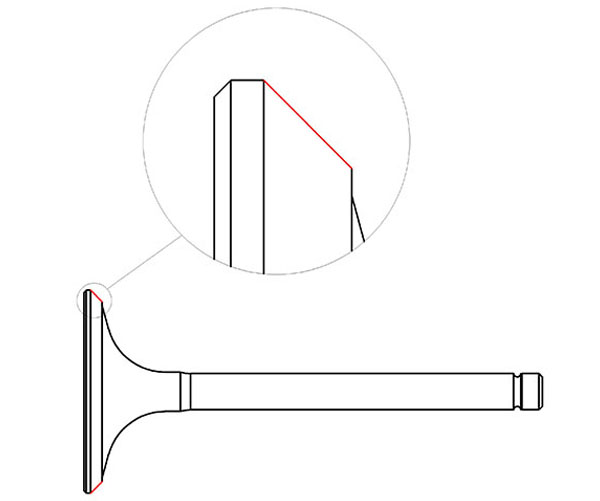

Feeding way & Positioning way Precision sliding table composed of linear guide. Moving according to air cylinder; Head face of engine valve positioning ,roller clamping assist. |

Loading & unloading systemLoading & unloading system The rails can meet different size valves and easy to adjust The rest actions should carry out with grinding except for loading & unloading system Loading & unloading system has proper protection measures and don't affect the operator to change the fixture, wheel and other toolings If the loading & unloading system is out of order, the machine will ring and stop the cycle. |

| Before Processing | ||

| Processing Range | Head diameter: 20-50 mm; Stem diameter: 5-8 mm; Ovrall length: 80-150 mm | |

| Material | 21-4N, 4Cr10Si2Mo Imported: SUH:3, SUH:35, etc. Hardness: 25-45 HRc | |

| Stem run out: 0.005 mm , Head run out: 0.1 mm, Seat angle: 44-70 degree | ||

| Grinding allowance: 0.02-0.2 mm | ||

| After Processing | ||

| Run out | Max ±0.02 mm | |

| Repeated accuracy | Max ±0.03 mm | |

| Roundness | Max Ra 0.003 mm | |

| Roughness | Max Ra 0.4 | |

| Air Pressure | 0.4-0.6 Mpa | |

| Water discharge | 20L/Min | |

| Wheel | CBN Wheel ( Customized ) | |

| Wheel speed | 60m/s | |

| Total power | 12 KW | |

| Current | 380V/50Hz | |

| Machine Size | 2250*2550*2350 mm | |

| Machine Weight | 3500 KG | |

Finish grinding seat face of engine valve Valve seat grinding machine is special purpose machine for engine valve. It is used for finish grinding seat face of engine valve. We have two types valve seat grinding machine. one type is used for conventional wheel, other type is used ceramics CBN Wheel |

By continuing to use the site you agree to our privacy policy Terms and Conditions.