© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Have you ever wondered how easy it was to make several forged products that you have come across? You would have been correct to guess that there are some special techniques used.

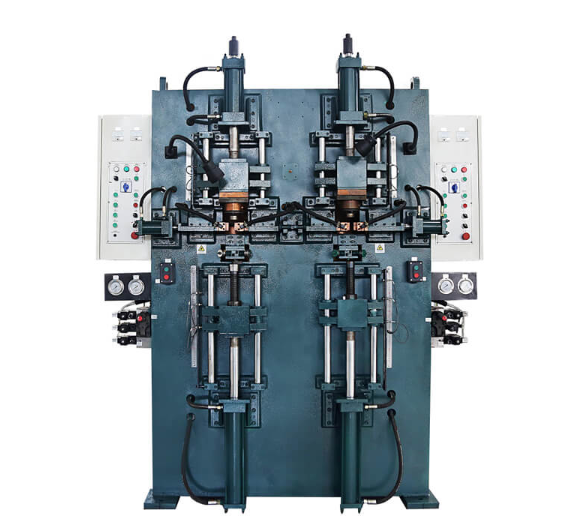

However, the most effective technique is the use of forging machines. Forging machines are a vital component of the manufacturing industry and are the key to achieving high-quality forged products.

You may be wondering, “What then are the benefits that I stand to gain from the use of these forging machines?” Do not stress too much, this article will give you a clear exposition of the benefits of a forging machine.

Forging machines offer several benefits that make them a preferred choice in various industries. Some of the benefits are:

The process of forging involves applying compressive force and localized heating to shape metals. This process results in a metal with a higher strength-to-weight ratio than other manufacturing processes.

The compressive force applied during forging aligns with the metal's internal grain structure, resulting in a stronger and more durable product. Additionally, forging eliminates the presence of internal voids and porosity, which can weaken the metal and reduce its overall strength.

Backed up by all these, the forging machine contributes to the speed at which these high-strength and high-weight products are formed.

Forging machines allow for the creation of parts with precise dimensions and intricate shapes, unlike other manufacturing processes. This precision is crucial in industries such as aerospace, automotive, and medical, where accuracy and consistency are critical.

Certainly, you would not want a larger size when you expected a smaller size of the forged product and vice versa.

A small increase in dimensions make cause wastage of raw materials and at the same time, a smaller-than-expected dimension affects the overall efficiency and quality of the product. Hence, a forging machine helps you to get the exact dimensions that you desire.

Forging machines contribute to a reduction in manufacturing costs. The process of forging involves shaping the metal by applying localized heat and pressure, resulting in minimal material loss.

This efficiency is particularly important in industries where high-value metals are used, such as titanium, nickel, and steel. Additionally, the high-quality products produced by forging machines have a longer lifespan, resulting in lower maintenance and replacement costs.

Forging machines are a critical component of the manufacturing industry. While the initial investment in forging machines can be significant, the long-term benefits in terms of efficiency and cost reduction make them a worthwhile investment for any manufacturing business.

The continued advancements in forging technology ensure that forging machines remain an essential tool in the manufacturing industry.

Are you reading to make a lasting investment in forging machines? You can always reach out to us and let us discuss your budget.

Contact us today for high-quality forging machines at prices that will not break the bank.

By continuing to use the site you agree to our privacy policy Terms and Conditions.