© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

The first good news in 2018 is order from India customer on engine valve grinding machine and three phase electrical upsetting machine for engine valve, as you can see from below picture. the delivery and package.

Engine valve manufacturding machine line is our hot slae product, from the very beginning of 2018, we sent the engine valve grinding machine and electrical upsetting machine out as we promised for our customer at first.

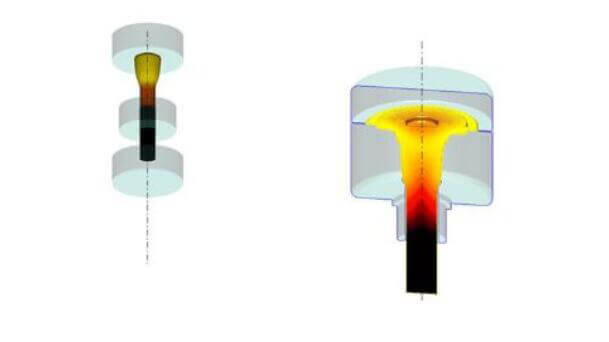

Upsetting is a kind technology:

A high current is passed into one portion of the material to be upset. Electrical resistance causes the component to heat up. Once this portion of the material reaches plastic state, cold material is pushed into the hot area via hydraulic force.

During open electrical upsetting, the bar material is positioned between the upsetting cylinder and the anvil plate or die. Two-part clamping jaws close around the bar and electrical current flows between the clamping jaws and anvil plate, heating the exposed portion of the component. The hydraulic cylinder exerts a controlled force on the cold end of the bar producing a shaped head. The material is upset to the required shape via the application of heat, pressure, flow and linear travel. In open upsetting techniques the component is then passed to a form tool (press) in the red hot state to finish. Closed techniques produce a finished component direct from the upsetting machine.

The upsetting axis is usually vertical and the stroke is hydraulically powered. The machines incorporate many features that ensure optimum cycle time, excellent repeatability, quick set-up and reliable operation for all types and sizes of valves.

Happy New Year for all friends.

Tianzhijiao engaged in offering excellent quality Electrical Upsetting Machine also know as engine valve centerless grinding machine to our valuable clients. The cold bar is placed in the machine jaws. A low voltage high amperage current is passed through it. Due to resistive power loss in job, It gets heated to plastic deformation stage. Hydraulic cylinder is used to gather the softened metal of job which results in bulb formation having temperature suitable for subsistence operation of impact forging. it can used widely in below indistries:

AEROSPACE

AUTOMOTIVE

CUTTING TOOLS

ELECTRICAL

INDUSTRIAL

OIL AND ROCK EXPLORATION

WHITE GOODS

By continuing to use the site you agree to our privacy policy Terms and Conditions.