© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

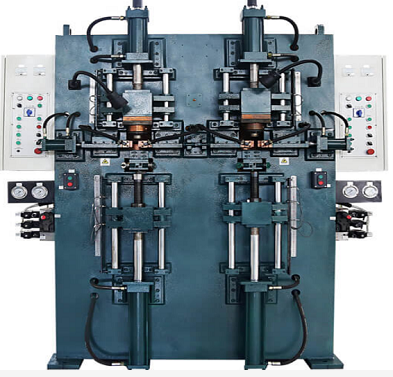

A forging machine is always used for forging objects into different shapes, which is usually done horizontally. Originally forging machine was developed for the production of bolts-head but nowadays it can be used to design different types of shapes.

The forging machine is usually done by upsetting operations which are known as upset forging. Though the press and the drop forging are done with a machine, traditionally, only the upset forging is referred to as a forging machine.

Typically, a forging machine is used for making beer blanks, shafts, axels, rod with flanges, and also similar parts, and they are a very essential machines for various industrial processes because of the different design they can be made to produce.

Usually, the upset machines are generally set on a horizontal axis which consists of a corresponding punch and two die parts. The die always has different impressions and corresponding punches or headed tools in which the die is consisting of two-part which one is movable alongside the die slide and the other is fixed to the machine parts.

The stock is cut to length and heated in an appropriate heating unit, which always fed the machine automatically. The stationary die grip that is fixed with the machine grip the hot work part of the machine, then the heading tool moves forward to the stock until the upsets are filled by the die cavity.

Moreover, immediately the upsetting is completed, the heading or the punching goes back to its original positions in which the moving grip die to move forward by releasing the components

Worthy of mention here is the fact that a forging machine contains a certain number of passes and die impressions

In a forging machine which is similar to drop forging, and it's not always certain you will get the exact shape in a single formation or pass. So, pass numbers are essential to finish the component, and depending on the unique complexity of the shape, type of materials, and the certain number of impression die.

It was very possible to forge one or more die impressions in a die which mostly depends on the geometries of the shape required. The type of die cavities required for different operations are always provided vertically where the gripper die is placed, the stocks are usually circulated step by step after completion of one operation and the other.

1. Production rate is high usually up to 4500 parts per hour

2. The operations are fully automated with less human interferences

3. It usually eliminates forging draft and flash

4. Its efficiency ratio is high because it ensures materials utilizations as the process doesn't waste materials.

As a leading brand with a high commitment to quality when it comes to the manufacture of high-standard forging machines and other types of forging equipment, you can count on us for the best products.

So, in case you need any of our products and services, kindly click here to contact us for any of our products and we will be glad to partner with you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.