© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Multi-purpose grinder machine is specail purpose machine for engine valve. It is used for rough grinding head diameter, head chamfer and seat face, Changing other program, the machine also can grinding head face of engine valve. Ranging from stem diameter 4.5 mm to 8 mm, Head diameter: from 17 mm to 40 mm, overall length from 70 mm to 130 mm. Our equipment is continually upgraded with latest technologies in processing engine valve. our machines can be single production and also can be connection production.

|

Stem diameter :

|

|

|

Overall length :

|

|

|

Head diameter:

|

|

VRG-400

Multi-purpose grinder is special purpose machine for engine valve. It is used for rough grinding head diameter, head chamfer, and seat face. Changing another program, the machine also can grind the head face of engine valve.

Ranging from stem diameter 4.5 mm to 8 mm, Head diameter: from 17 mm to 40 mm, overall length from 70 mm to 130 mm. Our equipment is continually upgraded with the latest technologies in processing engine valves.

our machines can be single production and also can be connection production.

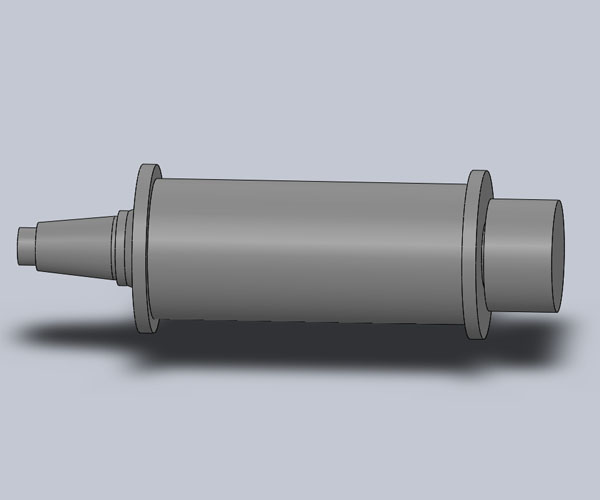

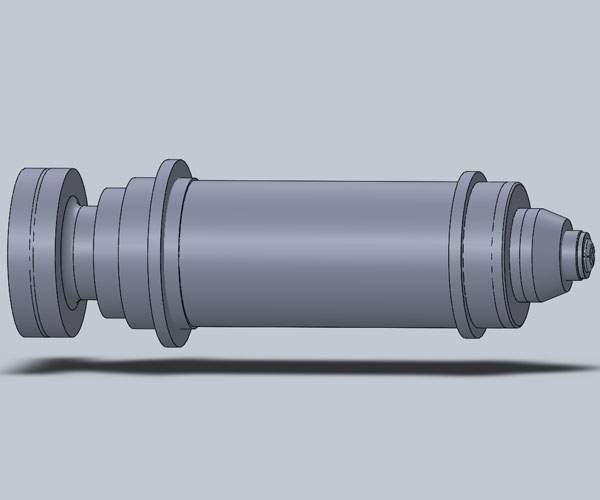

Mechanical Spindle Spindle speed: 6000 rpm; Adopt German FAG precision bearing; High precision; Easy to maintenance and changeover. |

Headstock spindle Spindle speed: 300-3000 rpm; Adopt German FAG precision bearing; Match single cone multi-contact precision spring collet. |

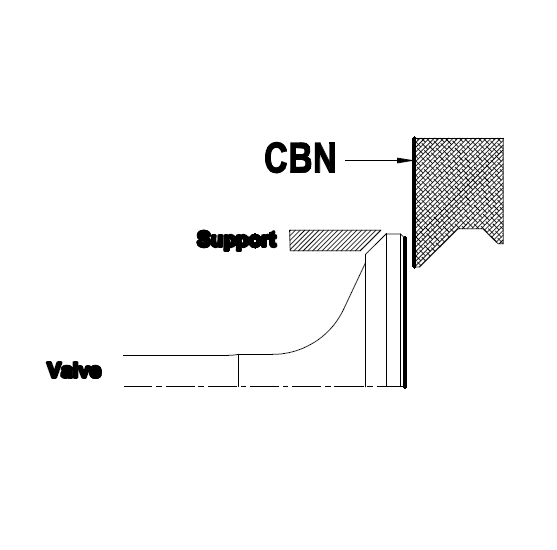

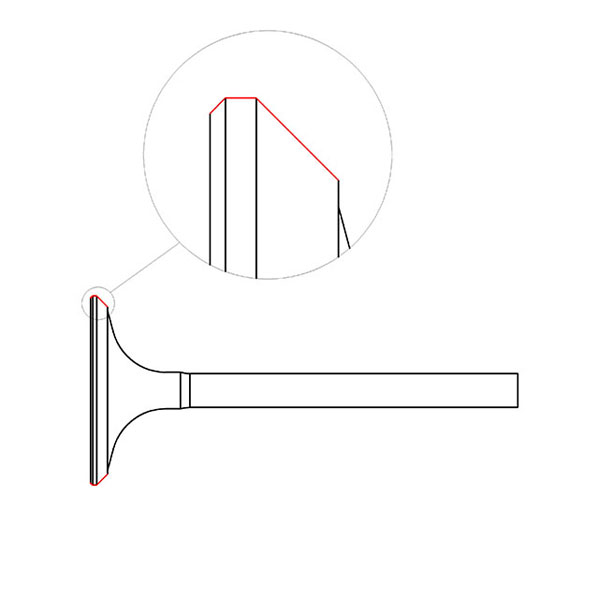

CBN Wheel High efficiency; Long life span; Electroplate treatment; CBN Profiled wheel. The wheel can rough grinding seat face, head diameter, and head chamfer; Can rough grinding undercut of engine valve; Can rough grinding head face of engine valve. |

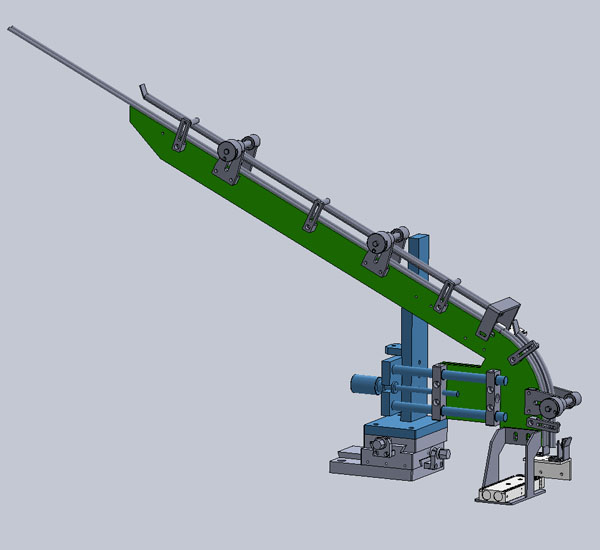

Loading & unloading system The rails can meet different size valves and easy to adjust; The rest actions should carry out with grinding except for the loading & unloading system; Loading & unloading system has proper protection measures and doesn't affect the operator to change the fixture, wheel, and other toolings; If the loading & unloading system is out of order, the machine will ring and stop the cycle |

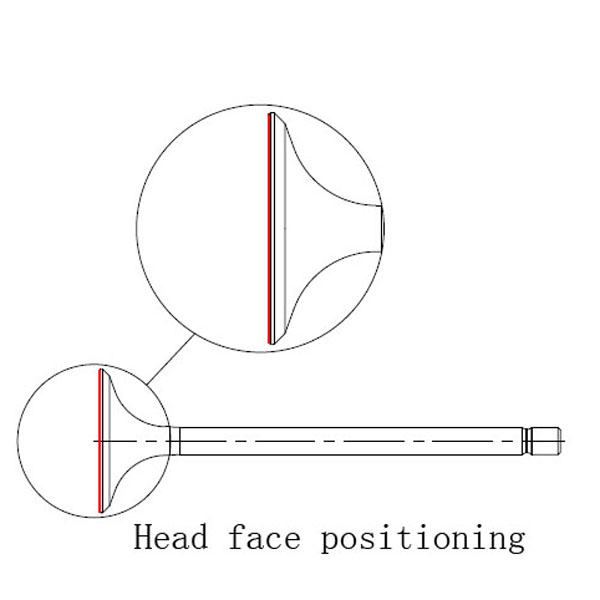

Feeding way & Positioning method Composed of ball screw and linear guide; Easy to maintenance and replacement. Stem tip position, OD assist. |

| Before process | ||

| Processing range | stem diameter: 5-10 mm, head dimeter: 20-50 mm, overall length: 70-150 mm | |

| Raw material | 21-4N, WNB, 4Cr10Si2Mo, Imported: SUH:3, SUH:35, Hardness: 25-45 HRC | |

| Run out of stem: 0.01 mm, Run out of top head: 0.1 mm | ||

| Seat Angle | 45~60 degree | |

| grinding allowance | 4 mm | |

| After processing | ||

| Processing accuracy | out cycle tolerance | Within ±0.03 mm |

| thickness of seat | Within ±0.03 mm | |

| surface treatment | Ra 1.6 | |

| Cycle time | 14s/piece | |

PLC Program 1: Rough grinding head face of lawn machine & motorcyle engine valve Engine valve multiple grinding machine is special purpose machine for engine valve. You can rough grinding head face of engine valve using CBN Wheel when you choose different program. The machine is suitable for mass rough grinding small engine valve |

PLC Program 2: Rough grinding head diameter, head chamfer and seatr face of engine valve Adapt CBN Profiled wheel. The machine can process different parts of engine valve when you choose matched program. Using Mitsubishi Q series control system, servo motion system and colorful touch screen. all parameter can be display on touch screen |

By continuing to use the site you agree to our privacy policy Terms and Conditions.