© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

If engine performance is your aim, or you are an automotive hobbyist, then you should most likely not be afraid of swapping camshafts in your engine. Moreover, you should find a reliable manufacturer of engine valve grinding machines.

However, the trick to making your car faster is not just replacing stock engine parts with performance engine part, but replacing it with the right performance parts and techniques.

This is where your understanding of valve timing becomes crucial in selecting the proper cam. Let’s get down to the core facts when engine performance is important.

Variable Valve Timing & Engine Performance

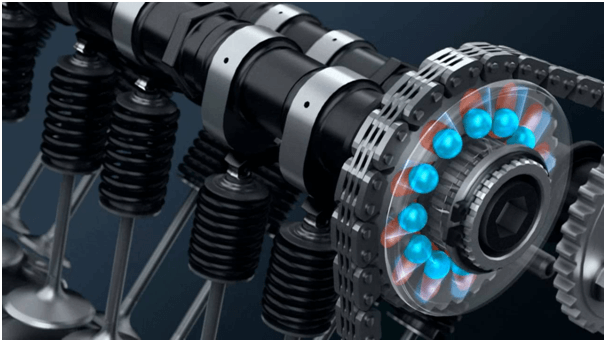

Most engines used the variable valve timing systems to avoid some of the flaws of the fixed valve timing.

The VVT is a fully flexible system, which could vary valve lift and intake and exhaust valve event timings independently for different engine speed and load conditions.

Practically, the more flexible a variable valve timing system becomes, the more complex and hence expensive it gets.

There are many different designs for achieving the VVT, they include:

1. Profile Switching Systems:

In this form of variable valve timing system, valve event timing and valve peak lift are capable of changing independently. The Profile switching system switches between two different camshaft profiles on one or both of the camshafts and is usually designed to change at a particular engine speed. This ability to change valve event timing, lift and duration makes these systems capable of providing a very high power output from a given engine and still comply with emissions legislation.

2. Variable Event Timing Systems:

Variable event timing systems are seen to be probably the most flexible type of variable valve timing system. The variable event timing system does not change peak valve lift, they are able to change both the phasing and the duration of valve events. Perfect about these systems is that they can be controlled to any setting between two extremes and are most effective when optimized for different engine speed and load conditions. In addition, reductions in part load emissions and fuel economy are also achievable through the full optimization of the variable event timing system.

3. Variable Lift Systems:

This form of VVT is divided into 2 forms:

a. Scales:

Here, the valve lifts such that its opening duration is unchanged.

b. Truncates:

Here, the lift profile such that the valve opening duration reduces as lift reduces.

Both of these types of Variable Lift system can work effectively when combined with a phase changing device. The VL system has a major benefit of throttling the cylinder by reducing the intake valve lift thus saving the pumping losses associated with the conventional throttle.

With any of these methods of the variable valve timing and engine performance that is more convenient for you, engine valve manufacuturing process can make sure the engine works well, you are sure to have a better engine performance with less emission and fuel consumption.

By continuing to use the site you agree to our privacy policy Terms and Conditions.