© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Recent technology has reveals a new engine valve grinding machine which provides petrol engines with the efficiency as well as the economy of diesels. This new engine valve also displays a more benign and manageable emission when compared with conventional petrol engines.

This latest automotive system also known as Intelligent Valve Actuation (IVA) has reached a sufficient stage of maturity after about six years of the development process. The new engine valve is now available to valve grinding machine manufacturers as well as component suppliers for development. This will serve as a more efficient boost when used in both hybrid and conventional cars.

Also, the new automotive system allows valve timing, duration and valve lift controlled independently and infinitely. This new invention has now broken the initially unbreakable mechanical link between the rotation of the crankshaft and the valve operations which has been considered a huge factor in the design of all piston engines for over a century now. Roger Stone, the technical director of Camcon and leader of IVA’s development describes this new valve engine as “a lifelong engine man”.

Again, the latest invention, offers a genuine proof that an engine could actually be entirely configured according to a driver’s needs. A significant aspect could be seen in the delivery of extreme flexibility in low-load situations, low speed and with very high power when needed.

The inventors of this new valve engine describes the development as even more important than the switch from carburetors to fuel injection or point ignition to engine management. Some say the IVA eliminates the last remaining analogue system from the engine design.

Likely as a further boost to engine efficiency, the new valve engine eliminates the compromises imposed by the existing less advanced variable valve timing systems and conventional camshaft timing. In addition, the IVA is uniquely adaptable to the more advanced and sophisticated cylinder deactivation protocol.

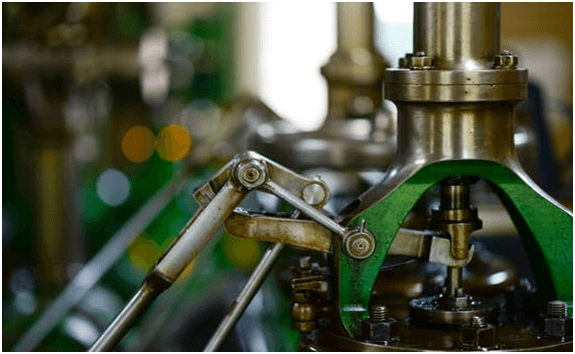

However, the new valve engine technology is based on the development of an electromechanical actuator systems on top of the engine. Each of the units drives a short camshaft which then opens a valve pair or a single valve. The entire system is enclosed in a large metal box at the engine top. Though this system runs on the traditional petrol, the idea is to achieve a more advanced engine which provides same efficiency as seen in the diesel engine.

So far, the new valve engine, has proven its durability. Now, major steps have been taken to get this into a more productive line.

By continuing to use the site you agree to our privacy policy Terms and Conditions.