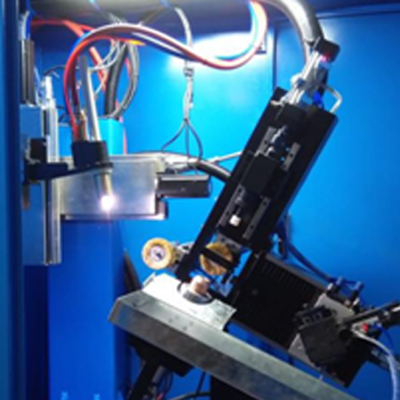

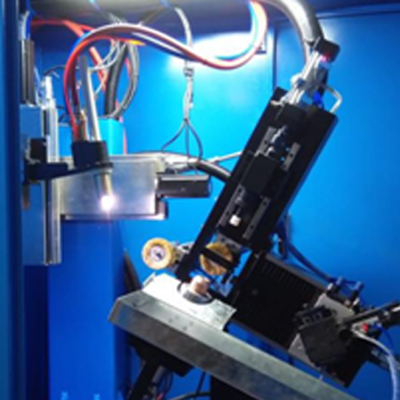

Plasma Welding Machine is special purpose machine for engine valve. It is used for welding seat face and tip end, which is conducive to the formation of a good weld quality.

During the welding process of the plasma welding machine, the plasma flow penetrates the molten pool to form small holes. Under the action of surface tension, the molten pool metal flows to the tail of the molten pool along the small hole. When the arc moves forward, the molten pool crystallizes to form a weld, which is conducive to the formation of a good weld quality.

Plasma welding machine applications include: surface welding, spraying and welding. By using low pulse welding current with adjustable frequency, plasma welding can control the arc energy in a better way, which is a high-quality welding method. The depth/width ratio of the weld is large, the heat-affected zone is narrow, the deformation of the workpiece is small, and there are many types of weldable materials.

High safety factor

Energy saving and environmental protection

High efficiency and low cost

Quenching way Quenching by TG-30 high-frequency machine, the machine bed is casting iron (HT250); Workpiece feed pneumatic control, automatic loading & unloading. |

Control system Adapts Mitsubishi PLC Control system, Mitsubishi motion system & Mitsubishi touch screen All parameters can be set and display on touch screen Can store more sets program, you can choose according to different process technology |

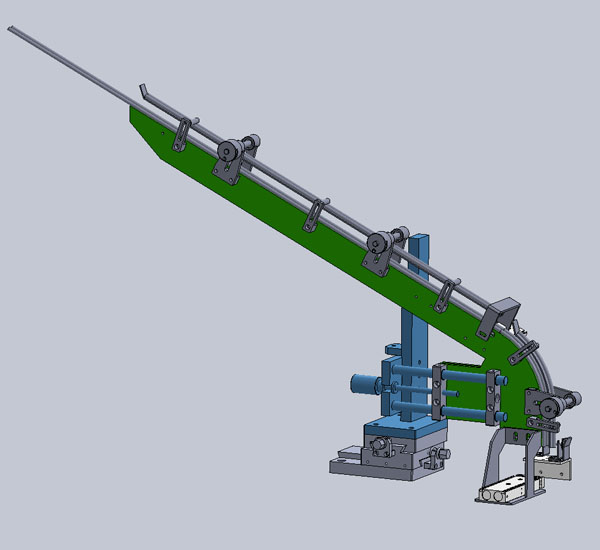

Feeding way Precision sliding table composed of linear guide. Moving according to air cylinder |

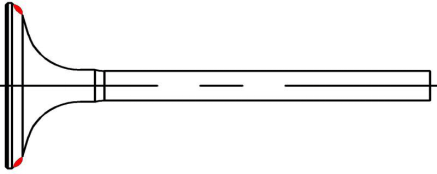

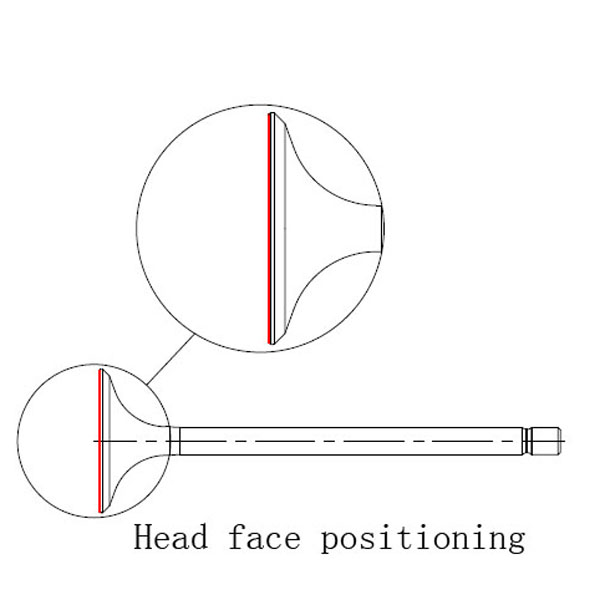

Positioning Way Head face of engine valve positioning Guide wheel assist |

Loading & unloading system The rails can meet different size valves and easy to adjust The rest actions should carry out with grinding except for loading & unloading system Loading & unloading system has proper protection measures and don't affect the operator to change the fixture, wheel and other toolings If the loading & unloading system is out of order, the machine will ring and stop the cycle. |

| Before processing | ||

| Processing range | Head diameter: 20-50 mm, Stem diameter: 5-10 mm, Length: 70-150 mm | |

| Material | 21-4N, 4Cr10Si2Mo, Imported: SUH:3, SUH:35,etc. Hardness: 25-45HRc | |

| Run out of OD | 0.1 mm | |

| Run out of head TOP | 0.1 mm | |

| Stem Diameter | 0<d<0.05 | |

| Head OD | 0<D<0.15 | |

| Straightness | <0.03 mm | |

| Valve Edge thickness | ≥0.8 | |

Quenching way Quenching by TG-30 high-frequency machine, the machine bed is casting iron (HT250); Workpiece feed pneumatic control, automatic loading & unloading. |

Control system Adapts Mitsubishi PLC Control system, Mitsubishi motion system & Mitsubishi touch screen All parameters can be set and display on touch screen Can store more sets program, you can choose according to different process technology |

Feeding way Precision sliding table composed of linear guide. Moving according to air cylinder |

Positioning Way Head face of engine valve positioning Guide wheel assist |

Loading & unloading system The rails can meet different size valves and easy to adjust The rest actions should carry out with grinding except for loading & unloading system Loading & unloading system has proper protection measures and don't affect the operator to change the fixture, wheel and other toolings If the loading & unloading system is out of order, the machine will ring and stop the cycle. |

By continuing to use the site you agree to our privacy policy Terms and Conditions.