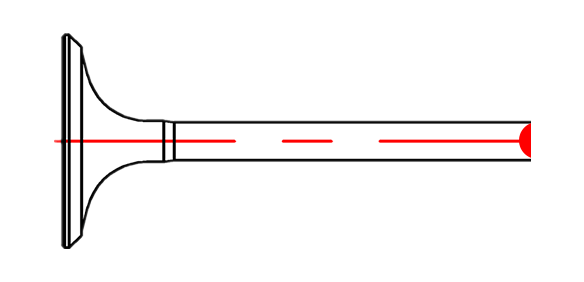

Plasma Welding Machine for Tip is special purpose machine for engine valve. It is used for welding tip of engine valve

Plasma Valve Tip Welding Machine

Product Description

Plasma Welding machine for tip is special purpose machine for engine valve. it is used for welding the tip of engine valve.

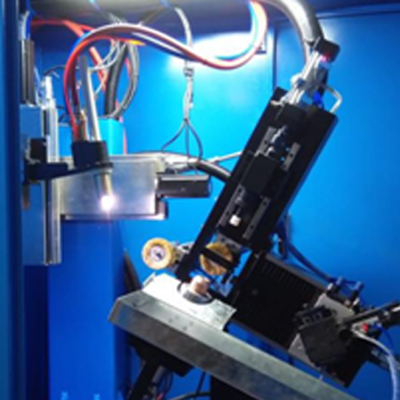

Quenching way Quenching by TG-30 high-frequency machine, the machine bed is casting iron (HT250); Workpiece feed pneumatic control, automatic loading & unloading. |

Control system Adapts Mitsubishi PLC Control system, Mitsubishi motion system & Mitsubishi touch screen All parameters can be set and display on touch screen Can store more sets program, you can choose according to different process technology |

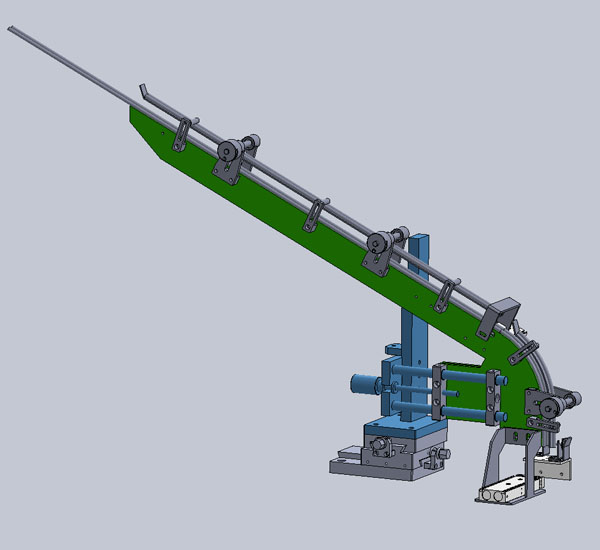

Feeding way Precision sliding table composed of linear guide. Moving according to air cylinder |

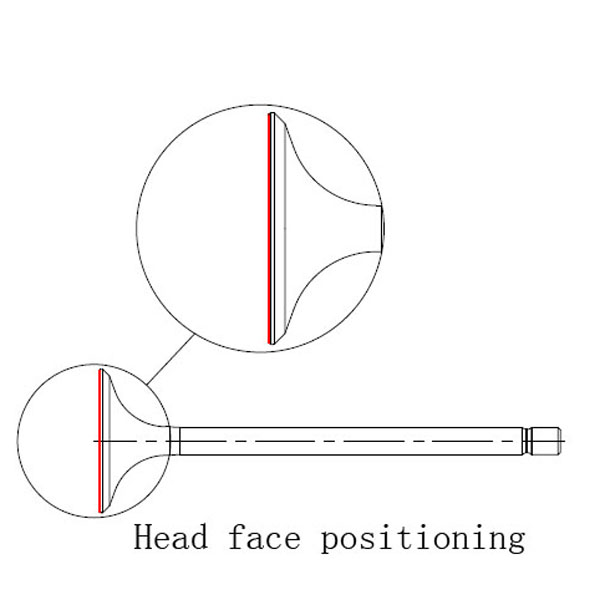

Positioning Way Head face of engine valve positioning Guide wheel assist |

Loading & unloading system The rails can meet different size valves and easy to adjust The rest actions should carry out with grinding except for loading & unloading system Loading & unloading system has proper protection measures and don't affect the operator to change the fixture, wheel and other toolings If the loading & unloading system is out of order, the machine will ring and stop the cycle. |

Technical Parameter | ||

Main Parameter | Max. Stroke of torch Y-axis | 300mm |

Turntable speed | 0.5-100r/s | |

Cycle time | 5-7s | |

Machine weight | 500Kg | |

Weld Parameter | Non-transfer arc current | 0-200A |

Transfer arc current | 0-200A | |

Transfer voltage | 55V | |

Feeder flow | 0-50g/min | |

Tungsten diameter | 3.2mm | |

Gas flow | 0-2.5L/min | |

Shielding gas flow | 0-25L/min | |

Cooling water pressure | >0.2Mpa | |

Temperature control of cooling water | 5-40℃ | |

Current | 220V.15A | |

Total power | 3KW | |

Plasma tip end of engine valve

By continuing to use the site you agree to our privacy policy Terms and Conditions.