© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

CNC cutting machine can be used in so many different areas, becoming increasingly more important in people’s life. To introduce CNC cutting machine in TZJ with more details, TZJ contains two products in this series, CNC rod cutting machine and CNC value cut off machine.

TZJ designs and manufactures CNC cutting machines using state-of-the-art technology to provide customers with a superior end product. Whether your business is a small shop, heavy-equipment manufacturer or steel service center, we have high performance cutting machines to meet your needs. our machine specialized in engine valve bar cutting.

First, for the CNC rod cutting machine, is used for cutting round bar for engine valve. And Rod cutting machine is special purpose machine for engine valve, it is used for cutting round bar. Stem diameter from 5 mm to 13 mm, overall length: no more less 450 mm. And there are many special features of it. In CNC rod cutting machine, it uses electrical spindle (4000 rpm to 8000 rpm the speed can be adjusted); spindle of wheel is bearing structure and can bear axial force. The machine bed and slide use HT250, heat treatment to eliminate stress and it is not easy to deformation. Workpieces feeding is controlled by servo motor to control the action of grinding and automatic cycle. What’s more, adjustment grinding amount is controlled by PLC and touch screen. Linear speed of wheel is around 120m/s. Transmission system is ball screw and linear guide. Equipped with automatic loading & unloading mechanism, all sealed sheet metal except for loading and unloading parts to prevent the liquid from leakage.

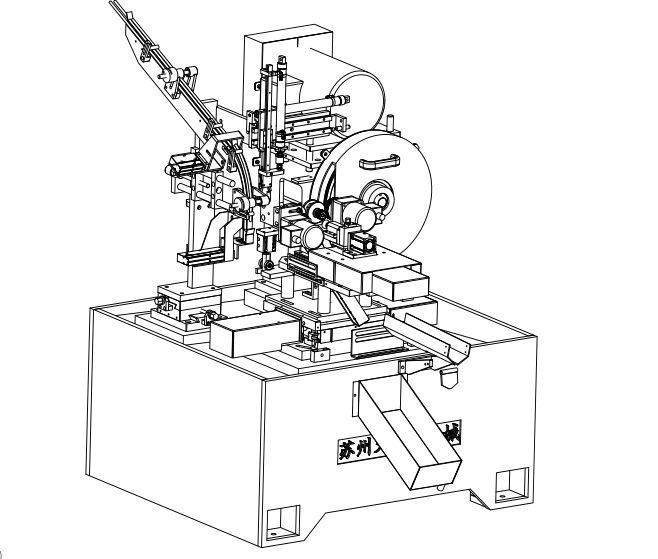

Next, for the CNC value cut off machine, which is special purpose machine for engine valves. Using CBN high speed wheel to cut the stem of engine valve in order to control the total length of engine valve. Ranging from Stem diameter: 5-8 mm, Head diameter: 20-50 mm, overall length: 80-150 mm. Valve cut off machine can be single production and also can be connection production. Our equipment is continually upgraded with latest technologies in processing engine valve. HT250 machine bed and feeding slider, tempering heat treatment to eliminate stress and it is not easy to deformation. Feeding of parts is controlled by double servo motor to achieve the action control of the amount of cutting and automatic cycle. The adjustment the amount of cutting is controlled by touch screen. can set permission password after commission. The speed of CBN Wheel on it is 80-140 m/s. Feed guide rail, slider and ball screw are lubricated automatically by electrical filling pump.

All sealed sheet metal except for loading & unloading parts (We can install safety door lock system; it is up to the customer needs). With automatic loading & Unloading mechanism. The frame can meet different size valve and easy to adjust. The new CNC value cut off machine has new design with water recovery apparatus device at the blanking way to prevent the fluid from leaking and alarm device. Last but not least, valve Cut off Machine is special purpose machine for engine valve. it is used to process engine valves (inlet valves and exhausted valves) in cars, motorcycles, trucks, and other engine valves.

Along with the rapid development of high-tech technology, CNC cutting machine also upgrades fast in recent years. It is obvious that CNC cutting machine and other related products will own a bigger market share in the future, with the support of government policies and support of brand-new materials or technology. If you are interested in CNC cutting machine, I believe you will choose a suitable item from the TZY. It is welcome for you to visit its official website and learn more about what you like.

By continuing to use the site you agree to our privacy policy Terms and Conditions.