© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

The engine valve seats and valves are of great importance. They play an imperative role in the mechanical industry. The valve seats are used to manage the heat of the valves. Generally, the valve seats conduct heat to the minimum. When the valves are going to shut, then they remove heat from the valve's head. If we do not take care of the valve seat, then the valves will get damaged soon. They may wear out in a short period. To keep the valves running for a long time, it is imperative to focus on the valve seats.

Engine valve seats should be excellent in every way. To make these valve seats efficient and durable, it is imperative to choose high-quality material. In older times, the engines with cast iron cylinder head cut down the valve seat from iron. They had to lead fuel and high octanes to keep the temperature down. The iron valve seats were able to reduce the pre-explosion, which could wear out the entire engine.

Engine valves had to be made up of steel material. Steel is a combination of iron and other metals. It contains a high percentage of Chromium. There were some applications in which the stem of the valve was light and hollow. Sodium was mixed at a high temperature to make the valves of high quality. The valve seats for this sort of engine were able to carry heat away quite efficiently.

With the cylinder heads made up of aluminum, the developers had to use aluminum to produce engine valve seats. These valve seats were able to fit into the aluminum as others could not be fitted. They have the capacity to manage and transfer heat properly. Aluminum is a corrosion-resistant alloy due to which it is of great significance. The developers had to use this material to improve the quality of the valve seats and valves.

Before picking up the material, the developers had to know the application. They create and developer valve seats and valves according to the application. The material is also picked after the consideration of the application. It is not possible to use steel engine valve seats for aluminum cylinder heads or vice versa. Otherwise, everything will go wrong.

Nonetheless, either the valve seats and valves are made up of steel or any other material; the top quality material has to be picked.

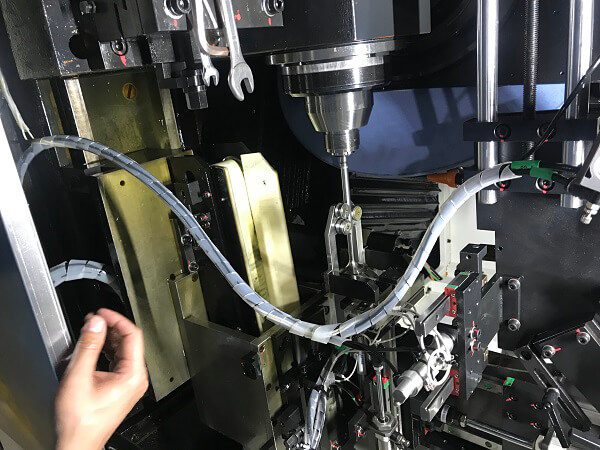

Engine valve seat grinding machine is used in diverse mechanical companies. This equipment is excellent to grind and cut the valve seats properly. It contains a digital program through which the companies can set the dimensions of the valve seats.

When it comes to the material quality of the valve seats, you have to consider a top-quality engine valve grinding machine. The grinding machine will be able to maintain the material quality of the valve seat. Also, it will produce such valve seats that will have great thermal conductivity. Due to this reason, these seats will be able to transfer heat from the valves to the head of the cylinder.

By continuing to use the site you agree to our privacy policy Terms and Conditions.