© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

When we start the car we are not usually aware of the multiple mechanical processes that have to take place for the engine to work. These occur thanks to the communion and joint work of a myriad of parts and moving parts that work in synchrony. One of these elements is the engine valves because without them it would not be possible to obtain the necessary energy from an engine.

The valves of an engine are the metallic elements that allow the entry of the fuel-air mixture into the cylinder and the exit of the mixture of the gases produced by its explosion. Without these mechanical elements, the operation of the motor would be unfeasible since its movement is vital for the energy required to move the wheels to be produced.

Engine valve manufacture and material

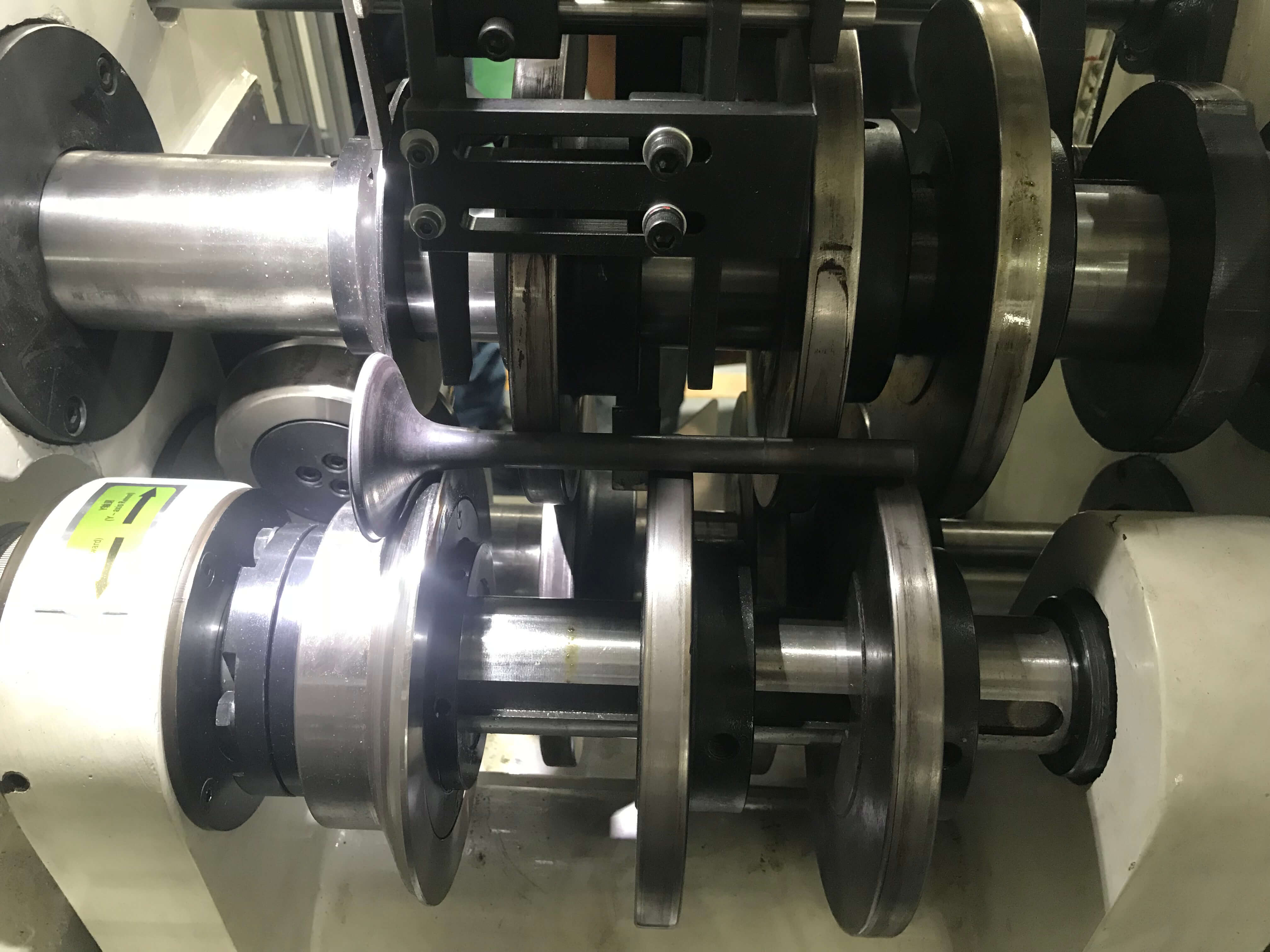

Structurally, a valve is made up of a long part called the valve stem or tail(commonly stem) and another upper part called the head (plate or valve head). Alloyed materials are used to manufacture them since they must withstand high temperatures in their operating cycle (up to 1000º centigrade).

The actual function is very simple. They are responsible for managing the entry of fuel and air (fuel-air mixture) into the cylinder. After the explosion of the mixture by the compression of the piston, they are the ones that allow the exit of the gases resulting from this explosion.

Technically they are located on the cylinder head. The wide part (valve head) rests on the cover, adjusting perfectly to correctly seal the cylinder. The lower part or stem is located inside the guide, limiting itself to completing the opening and closing movement ordered by the camshaft and springs.

No, the answer is no. The intake valve (where the mixture enters) is larger than the exhaust valve (where the gases exit). The reason for this different size is due to the conditions under which intake and exhaust occurs. The pressure at which the mixture enters is similar to that existing in the atmosphere so that in order to favor the process, its size is larger.

On the contrary, when the mixture has already exploded, the gases are at a higher pressure, so it is not necessary for their size to be so large. In addition, there is also a difference in the materials with which they are manufactured. The intake valve supports about 200º centigrade and the exhaust valve around 700º centigrade, so its components are stronger than those of the first one.

Finally, to correctly distinguish one type of valve from the other, we only have to look at the size of its head and its shape . We know that the intake ones have a larger head but in addition it is flat on the front, however the exhaust ones, in addition to having a smaller head, have a more conical shape on the front.

If a valve breaks, the first thing that will happen is that the explosion or expulsion of the gases will not be carried out correctly. This is due to the fact that when the valve does not rest well on the engine cover, the gases will leak and therefore a compression and thermal imbalance will occur, causing a major failure.

The main problem with which the valves have to fight is their little or no cooling, because if the engine is well lubricated there is no risk of failure. Solving such a fault has a variable cost, as they will depend on how they have failed and the damage that has occurred to the engine. The unit cost of a valve is very low, since its manufacture is economical, however, the final figure will vary depending on the type of valve and problem detected.

Valves are elements that have the simple function of closing and opening the gas intake and exhaust ducts , having the main function in the combustion of the air-fuel mixture.

The valves with the greatest acceptance today are the so-called "plate" valves, due to their inverted plate shape in their vital part, that is, the one that opens and closes the pipes.

From the center of them begins what is called "spike", a cylindrical extension that moves the valve , although the "informal" name is also frequent to call Head to valve plate, and tail to spike.

They are manufactured cast and machined in special steels because what is sought is to withstand the high temperatures that gases reach in their operation.

The heat differences between exhaust and intake allow special alloys to be used in the exhaust valves (withstanding 1000 degrees Celsius )

In addition to being fairly inexpensive to manufacture, these valves allow little passage area , less friction and appropriate shape for the correct flow of gases. The only disadvantage that these have is the little or no refrigeration that they present.

By continuing to use the site you agree to our privacy policy Terms and Conditions.