© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

The introduction of engine valves to the world of the automobile industry has provoked several car manufacturers around the world to up their manufacturing game. It is no wonder that cars are modified consistently and frequently to meet the escalating demand of the customers, and it has led to the production of engine valves, which are considered to be an excellent addition to the modern vehicles.

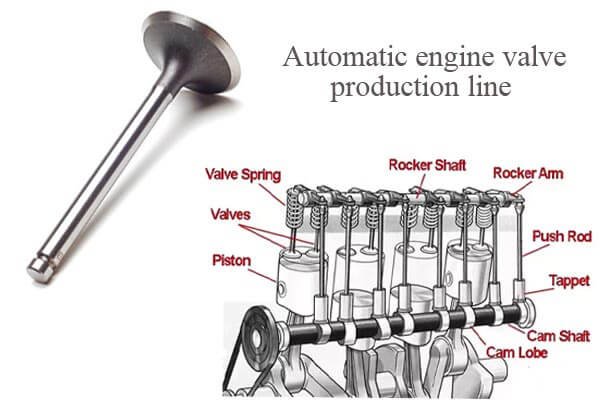

Engine valves are regarded as few of the important components in an automobile industry, which are installed in modern cars. Engine valves are also installed to preexisting cars using advanced tools and tremendous craftsmanship and manufacturing skills, to upgrade its features.

However, with an increase in the demand of automatic engine valves production line, it is noticeable that they are purchased for a hefty amount, which signifies the importance of owning an engine valve production line to a car manufacturer.

It has recently come to spotlight that a majority of the car manufacturing companies have started initiatives of producing their own car manufacturing line, which requires them to devise a proper plan for the production of the line on their terms. The manufacturers of cars parts have started taking complete responsibility for catering to the design, production, testing, quality assurance, and marketability of the product. Additionally, a majority of the automobile manufacturers have de-marginalized the supply of the car parts to an extent; instead, they have started investing the resources in the production and assimilation of their own engine valve production line.

Now, why is it accurately important to have your own engine valve production line? The following benefits highlight the significance of having an engine valve production line to a car manufacturer’s company:

When manufacturing a vehicle, it is highly imperative to make sure that the precision of the components installed is intact and secured. A similar principle is applicable to having a personalized engine valve production line, as it guarantees the precision of the engine valve. If the precision of the engine valves is not up to the standards, the team of mechanics at any automobile company can take care of the problem using its resources. It allows the car manufacturers to control and customize the overall precision and function of the engine valves.

When a vehicle is being manufactured, it requires a car’s manufacturer to communicate frequently with the supplier to make sure that the engine valves are produced according to the requirements of the manufacturer.

Also, if the engine valve is purchased from miscellaneous auto-part suppliers, it will require the car manufacturer to communicate with different vendors for the comparison of the quality, which could be a time-consuming process. It is recommended to start investing the resources in the production of your own engine valves line to save the occurrence of communication costs.

Investing in the production of a personalized engine valve line is geared at saving human costs. As mentioned earlier that the custom engine valve manufacturing line guarantees precision and exactitude of the component to a car’s manufacturer, it requires few people to participate in accomplishing the job, which would save human cost to an extent.

The overall objective of having your own engine valve grinding machine is to achieve an exact procurement of the production of vehicles within a given timeframe. It also saves the occurrence of miscellaneous expenses along with the human costs and communication costs, and it allows you to invest the residual resources in the advancement of your automatic engine valve manufacturing production line.

By continuing to use the site you agree to our privacy policy Terms and Conditions.